- Home Page

- Company Profile

-

Our Products

- PVC Foam Board

- PVC Board

- Decorative PVC Foam Board

- PVC Foam Board

- PVC Plywood

- PVC Foam Board

- Rigid Pvc Board

- Decorative PVC Foam Board

- PVC Termite Board

- Pvc Water Proof Board

- PVC Foam Board for Boat Building

- Furniture PVC Foam Board

- Axardeep PVC Board

- PVC Solid Sheet for Kitchen

- Closed Cell Pvc Foam Sheet

- Prelaminate Pvc Foam Sheet

- Pvc Celuka Board

- Waterproof PVC Sheet

- Water Proof PVC Foam Board

- PVC Plywood Board

- PVC Foam Board

- Skinning PVC Foam Sheet

- Rigid PVC Board

- PVC Sign Board for Kitchen

- PVC Sun Boards

- PVC Solid Sheet

- Turmite Proof Furniture Sheet

- Pvc Hybrid Board

- WPC Foam Sheet

- WPC Solid Door

- PVC Foam Sheet

- PVC Ply Board

- PVC Board

- Rigid WPC Board

- PVC Sun Board Sheet

- WPC Door Frame

- WPC Board

- WPC Foam Board

- PVC Sheet

- PVC Sign Board

- Pvc Door

- Pvc Compound

- PVC Foam Board

- Contact Us

NFC BOARD

NFC BOARD Specification

- Wood Type

- Wooden

- Application

- Other

- Surface Materials

- Polished

- Material

- Wooden

- Open Style

- Engraved

- Door Type

- Skin Moulded

- Surface Finishing

- Other

- Size

- 2440 x 1220 mm (8x4 ft)

- Color

- Brown

- Thickness

- 3-25 Millimeter (mm)

- Design

- Modern

NFC BOARD Trade Information

- Minimum Order Quantity

- 100 Sheets

- FOB Port

- VADODARA

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Supply Ability

- 10000 Sheets Per Day

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About NFC BOARD

NFC BOARD

NFC Board Natural Fibre Composite Board is made using the complex PTF technology, which for the first time builds a homogenous bonding between the natural fibre and the polymer. This creates a material with the natural look and feel of wood and at the same time is resistant to water, sun, wind and cold that does not splinter-even after many years.

AXARDEEP POLYMERS PVT. LTD. - Pioneer & Leading Manufacturer of NFC Board in India

About Us

AXARDEEP POLYMERS PVT. LTD. is a trusted pioneer and leading manufacturer of NFC Boards (Natural Fiber Composite Boards) in India. Combining the strength of natural fibers with advanced polymer technology, our NFC Boards offer an eco-friendly, sustainable alternative to conventional wood and composite boards.

With a strong focus on innovation, durability, and green manufacturing, AXARDEEP provides high-quality NFC Boards that meet diverse application needs-from furniture manufacturing to interior decor-while promoting sustainability and environmental responsibility.

Product Overview

AXARDEEP NFC Boards are manufactured using natural fibers (such as coir, jute, hemp) combined with polymer resins, creating a strong, lightweight, and moisture-resistant composite board. These boards are ideal for use where environmental sustainability and mechanical strength are both desired.

Key Features:

- Made from 100% Natural Fibers and Polymers

- Lightweight yet High Strength & Stiffness

- Water Resistant and Dimensionally Stable

- Eco-Friendly, Biodegradable, and Recyclable

- Termite and Pest Resistant

- Excellent Thermal & Acoustic Insulation Properties

- Suitable for Lamination and Surface Finishing

- Custom Sizes and Thickness Available

Technical Specifications:

|

Property |

Specification |

|---|---|

|

Material Composition |

Natural Fibers + Polymer Resin |

|

Density |

600 - 900 kg/m3 |

|

Thickness Range |

3 mm to 25 mm |

|

Standard Size |

2440 x 1220 mm (8x4 ft), Custom Sizes Available |

|

Water Absorption |

< 2% |

|

Flexural Strength |

20 - 35 MPa |

|

Impact Resistance |

High |

|

Termite Resistance |

100% Resistant |

|

Thermal Conductivity |

Low (Good Insulator) |

|

Surface Finish |

Smooth, Ready for Lamination or Painting |

|

Fire Resistance |

Available on Request |

Applications of NFC Boards

- Furniture Manufacturing (Tables, Cabinets, Shelves)

- Wall Paneling and False Ceilings

- Partition Walls and Interior Decoration

- Packaging and Pallet Boards

- Acoustic Panels and Insulation

- Automotive and Transportation Interiors

- Sustainable Construction Material

Why Choose AXARDEEP NFC Boards?

- Pioneer in NFC Board Manufacturing in India

- Commitment to Sustainable & Eco-Friendly Products

- Superior Quality Control & Advanced Manufacturing Process

- Customization to Meet Client Specifications

- Durable and Long-Lasting Performance

- Competitive Pricing with Pan-India Delivery

- Expert Technical Support and After-Sales Service

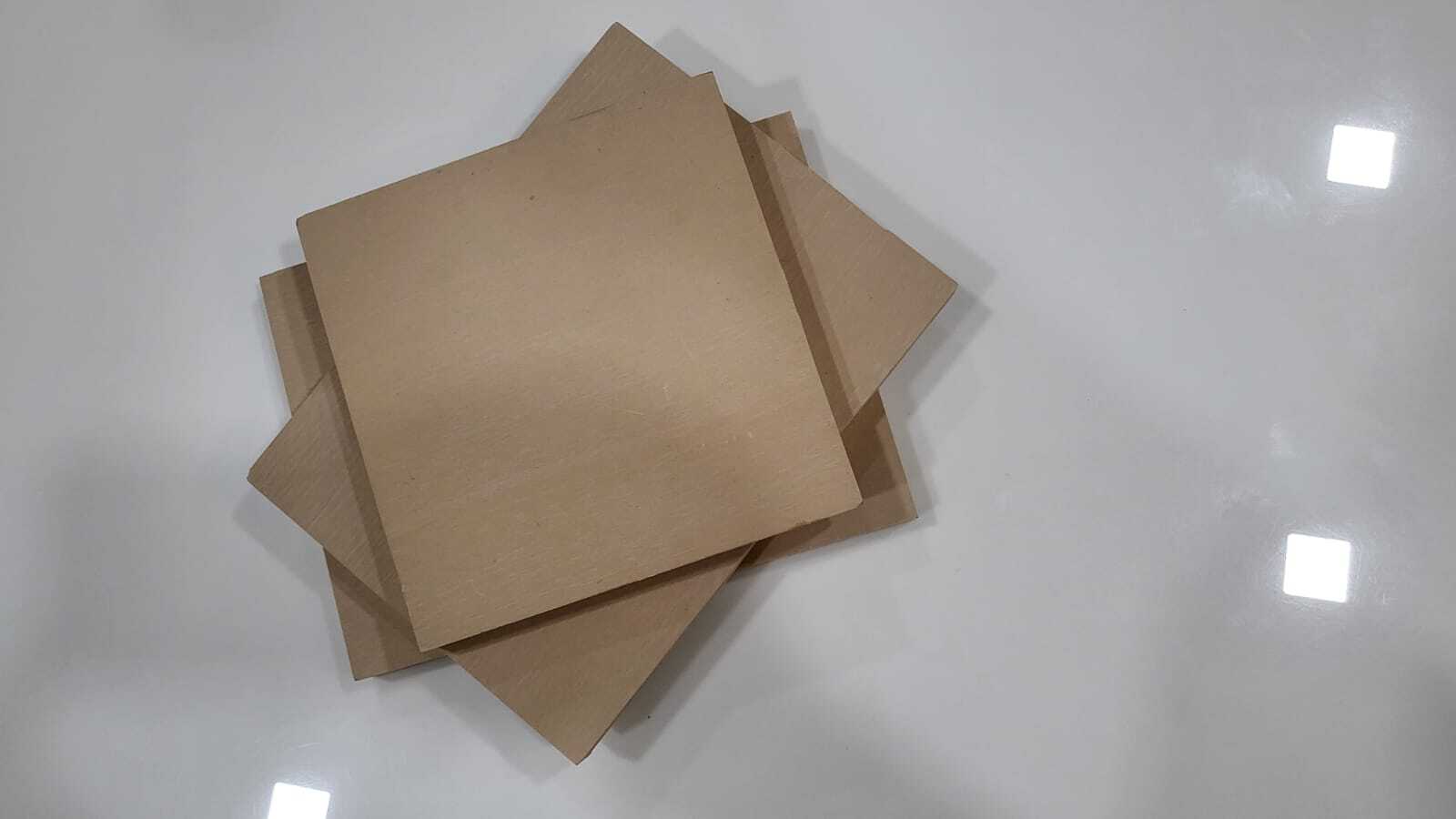

Premium Modern Design for Versatile Spaces

The NFC Board is tailored to meet the creative needs of modern architects and interior designers. Its engraved pattern and polished finish deliver both visual appeal and durability. The wide range of available thicknesses makes it ideal for custom doors, partitions, or wall applications in homes and commercial environments.

Precisely Crafted Wooden Panels

Each board is meticulously crafted using quality wood, ensuring structural integrity and a luxurious look. The standardized 2440 x 1220 mm size offers flexibility for a variety of installation scenarios, from residential interiors to commercial projects.

FAQs of NFC BOARD:

Q: How can NFC Boards be utilized in interior design projects?

A: NFC Boards are suitable for doors, partitions, wall panels, and custom furniture elements. Their modern, engraved appearance enhances contemporary spaces, while the versatile sizing allows for easy integration into various interior layouts.Q: What is the process of ordering NFC Boards for bulk requirements?

A: You can place bulk orders by contacting our distributor, exporter, manufacturer, supplier, or trader network in India. Orders can be customized in terms of thickness and design to meet your specific project needs.Q: When is the ideal stage in construction to install NFC Boards?

A: NFC Boards are best installed after the primary structure is complete and before final interior finishing. This ensures precise fitting and maintains the quality of the polished surface during installation.Q: Where are NFC Boards primarily manufactured and distributed?

A: These boards are manufactured and distributed across India, with a strong network of suppliers, traders, exporters, and manufacturers providing accessibility nationwide.Q: What benefits do NFC Boards offer compared to other wooden panels?

A: NFC Boards stand out due to their modern design, engraved detailing, and durable, polished surface. Their range of thicknesses and standard sizing make them adaptable for various sophisticated interior solutions.Q: How should NFC Boards be maintained for longevity?

A: Routine dusting and gentle cleaning with a damp cloth will preserve the polished finish. Avoid abrasive cleaners or excessive moisture to ensure the board retains its aesthetic and structural qualities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in WPC Door Frame Category

Digital Print Wpc Soild Door

Price 200 INR / Square Foot

Minimum Order Quantity : 50 Square Foots

Application : Residential, Commercial

Size : Standard

Surface Finishing : Finished

Color : Brown

WPC Solid Door Frame

Price 95 INR / Foot

Minimum Order Quantity : 100 Feet

Application : Residential, Commercial

Size : 75 mm x 45 mm x 2100 mm

Surface Finishing : Finished

Color : Brown

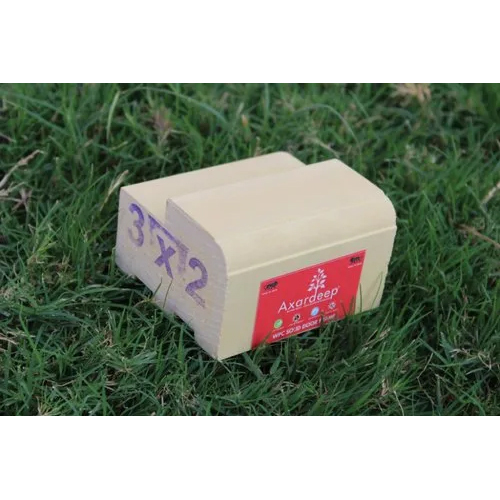

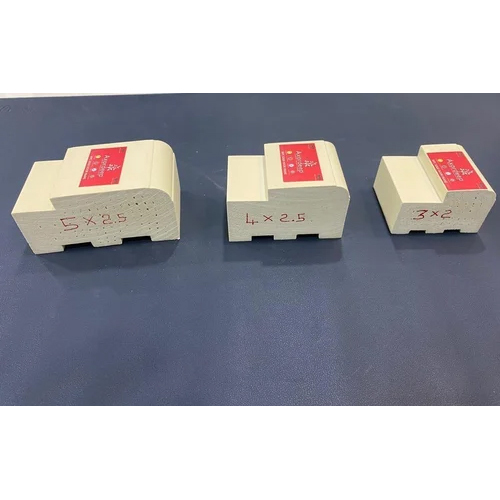

WPC Door Frame

Price 160 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Commercial

Size : 3"x2", 4"x2.5", 5"x2.5", 5"x2.75",

Surface Finishing : Other, Smooth, Wood Texture, Primer Coated

Color : Brown

Axardeep WPC Door Frame

Price 95 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Application : Residential, Commercial

Size : Standard

Surface Finishing : Finished

Color : Brown

"We are mainly looking for Bulk Order or Wholesale Inquiries"