- Home Page

- Company Profile

-

Our Products

- PVC Foam Board

- PVC Board

- Decorative PVC Foam Board

- PVC Foam Board

- PVC Plywood

- PVC Foam Board

- Rigid Pvc Board

- Decorative PVC Foam Board

- PVC Termite Board

- Pvc Water Proof Board

- PVC Foam Board for Boat Building

- Furniture PVC Foam Board

- Axardeep PVC Board

- PVC Solid Sheet for Kitchen

- Closed Cell Pvc Foam Sheet

- Prelaminate Pvc Foam Sheet

- Pvc Celuka Board

- Waterproof PVC Sheet

- Water Proof PVC Foam Board

- PVC Plywood Board

- PVC Foam Board

- Skinning PVC Foam Sheet

- Rigid PVC Board

- PVC Sign Board for Kitchen

- PVC Sun Boards

- PVC Solid Sheet

- Turmite Proof Furniture Sheet

- Pvc Hybrid Board

- WPC Foam Sheet

- WPC Solid Door

- PVC Foam Sheet

- PVC Ply Board

- PVC Board

- Rigid WPC Board

- PVC Sun Board Sheet

- WPC Door Frame

- WPC Board

- WPC Foam Board

- PVC Sheet

- PVC Sign Board

- Pvc Door

- Pvc Compound

- PVC Foam Board

- Contact Us

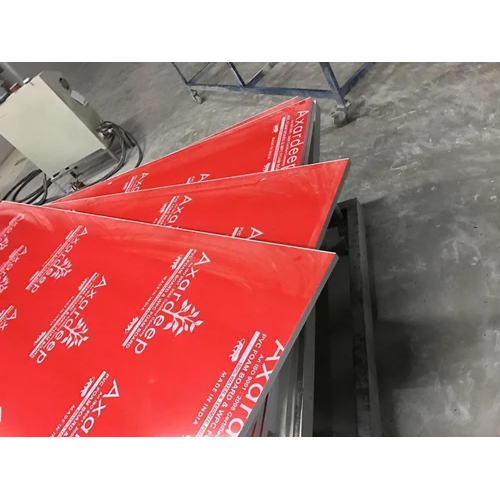

WPC Sheet

WPC Sheet Specification

- Print Type

- Plain

- Usage & Applications

- Industrial

- Finish Type

- Glossy

- Application

- Industrial

- Material

- PVC Resin + Wood Fiber + Chemical Additives

- Product Style

- Plain

- Characteristics

- Eco-Friendly

- Thickness

- 5-30 Millimeter (mm)

- Shape

- Square

- Color

- Brown

- Size

- 2440mm x 1220mm (8ft x 4ft)

- Pattern

- Plain

WPC Sheet Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 500 Square Foots Per Day

- Delivery Time

- 7 Days

About WPC Sheet

Pioneer Manufacturer of WPC Sheets in India

AXARDEEP POLYMERS PVT. LTD. is a trailblazer in the manufacturing of WPC Sheets (Wood Plastic Composite Sheets) - an advanced, eco-friendly substitute for plywood and conventional wood panels. Engineered using state-of-the-art extrusion technology, our WPC sheets are known for their superior durability, water resistance, and zero maintenance.

Product Overview

Our WPC Sheets are made using a unique blend of wood fiber, PVC polymer, and high-performance additives, offering a robust material that is 100% waterproof, termite-proof, and weather-resistant. These sheets are widely used in interior and exterior applications including furniture manufacturing, paneling, partitions, signage, and CNC decorative work.

Technical Specifications:

|

Specification |

Details |

|---|---|

|

Material Composition |

PVC Resin + Wood Fiber + Chemical Additives |

|

Density |

0.45 - 0.80 gm/cm3 |

|

Standard Thickness |

5mm to 30mm (Custom options available) |

|

Sheet Size |

2440mm x 1220mm (8ft x 4ft) |

|

Surface Finish |

Smooth, Matte, Glossy, Wood Textured |

|

Color Options |

White, Grey, Brown, Custom Colors |

|

Water Absorption |

0% - Fully Waterproof |

|

Termite & Pest Resistance |

100% Proof |

|

Fire Resistance |

Fire Retardant Grade Available |

|

Paint & Laminate Compatibility |

PU, Acrylic, Laminate, PVC Foil Compatible |

|

Machinability |

CNC Friendly, Can be cut, drilled, screwed, routed |

Key Features of AXARDEEP WPC Sheets

- 100% Waterproof - Ideal for wet areas

- 100% Termite and Borer Proof

- High Strength & Dimensional Stability

- Eco-Friendly and Recyclable

- Excellent Nail, Screw & Adhesive Holding

- Smooth Surface for Painting, Laminating & Routing

- Non-toxic, Lead-Free Formulation

- Weather & UV Resistant - Suitable for Exterior Use

Our Manufacturing Leadership

AXARDEEP POLYMERS PVT. LTD. stands among the pioneers of WPC Sheet manufacturing in India. With years of research, innovation, and a strong manufacturing base, we produce world-class WPC solutions trusted by architects, builders, interior designers, and fabricators across the country.

Our fully automated production facility ensures consistent quality, bulk supply capability, and customized solutions.

Applications of WPC Sheets

- Modular Furniture & Cabinets

- Bathroom Vanities & Kitchen Units

- Partition Walls & Wall Paneling

- Decorative CNC Cut Panels

- Exterior Cladding & False Ceilings

- Signage Boards & Shop Displays

- Door Frames & Panel Inserts

Comparison: WPC Sheet vs. Traditional Plywood

|

Feature |

WPC Sheet |

Plywood |

|---|---|---|

|

Waterproof |

Yes |

No |

|

Termite Proof |

Yes |

No |

|

Fire Retardant |

Optional |

No |

|

Eco-Friendly |

Yes |

No (Contains Formaldehyde) |

|

Maintenance |

Low |

High |

|

Workability |

Excellent |

Good |

High-Performance Industrial WPC Sheets

These WPC sheets combine strength and sustainability, providing a reliable solution for demanding industrial settings. The blend of PVC and wood fiber ensures enhanced durability and resistance to wear, while the glossy finish gives a polished surface ideal for diverse uses. Suitably sized, these sheets are efficient to handle and install, matching varied industrial requirements.

Eco-Conscious Manufacturing and Materials

Manufactured from eco-friendly materials including recycled PVC resin and wood fiber, WPC Sheets are a smart option for environmentally responsible projects. The combination reduces landfill waste and minimizes environmental impact during both production and product lifespan, supporting green initiatives in industrial supply chains.

FAQs of WPC Sheet:

Q: How are WPC Sheets manufactured and what materials are used?

A: WPC Sheets are produced through a composite process that binds PVC resin, wood fibers, and chemical additives under high temperature and pressure. This method creates a sturdy, uniform product suitable for industrial use.Q: What are the primary industrial applications for WPC Sheets?

A: WPC Sheets are popularly used in various industrial contexts, including partitioning, cladding, fabrication, storage, and processing facilities due to their strength, durability, and resistance to moisture and chemicals.Q: When is it recommended to use a WPC Sheet with a thickness between 5-30 mm?

A: Sheets in this thickness range are optimal for structural and protective applications where extra rigidity, impact resistance, or insulation is desired. Thicker sheets are typically chosen for heavy-duty or load-bearing purposes.Q: Where can WPC Sheets be sourced in India?

A: These sheets are widely available through distributors, exporters, manufacturers, suppliers, and traders across India, catering to industrial supply needs.Q: What makes the glossy finish of these sheets beneficial for industrial environments?

A: A glossy finish not only enhances the sheets aesthetic appeal but also facilitates easy cleaning and maintenance, helping prevent dust accumulation and prolonging surface life in busy industrial areas.Q: How does using WPC Sheets benefit sustainable industrial practices?

A: WPC Sheets embody eco-friendly manufacturing by incorporating recycled PVC and wood fiber, reducing the use of virgin materials, and supporting greener supply chain processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Foam Sheet Category

PVC Foam Sheet

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Industrial, Commercial, Residential

Material : Pvc

Color : White

Size : Standard

Closed Cell PVC Foam Sheet

Price 120 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Commercial

Material : Pvc

Color : White

Size : Standard

White PVC Foam Sheet

Price 120 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Industrial, Commercial, Residential

Material : Pvc

Color : White

Size : Standard

HI Density WPC Foam Board

Price 120 INR / Square Foot

Minimum Order Quantity : 50 Square Foots

Application : Industrial

Material : Other, WPC

Color : Brown

Size : Standard

"We are mainly looking for Bulk Order or Wholesale Inquiries"